color case hardening temperature

Color Case Hardening is a process for the surface hardening of steel which results in a decorative mottled-color finish. Color Case Hardening Temperatures Read 7000 times sakoman.

Physical Chemistry What Explains The Case Hardening Color Effect Chemistry Stack Exchange

From the earliest guns that were.

. Posted on january 28 2017 by brian lohman. It was well known that the sharpness and hardness of a weapons edge could. COLOR CASE HARDENING READ.

We keep our temperatures below hardening temperatures. Dont go over 1350. It is heated to somewhere around 1200 to 1400 degrees.

The origins of case-hardening. Color Case Hardening Temperatures. Recommendations to highly polish all parts and recommendations to not ex -.

This can be done in matte or gloss. Color case hardening temperatures read 6778 times sakoman. Color case hardening steel ----- 1998.

Please email howell arms. Around 1400 BC hardening methods began to appear in armouries around the world. The fibrillated micro fibers are often used in.

Wyoming Armory is a custom gunsmithing shop where we build custom firearms but one of our specialities is tradional bone charcoal color case hardening. Temperatures from 1250 to 1500 F and heating times of from 1 to 5 hours. Most of the newer.

To achieve these results we use the traditional method of. We keep our temperatures below hardening temperatures. Senior Forum Member Offline Posts.

Color Case Hardening is a process for the surface hardening of steel which results in a decorative mottled-color finish. Here at Tyler Gun Works we are able to Color Case items others cant due to our ability to work at lower temps. Feb 20 th 2006.

Our color case hardening process is done with a digital controlled furnace to insure a perfect temperature with each job. Color case hardening is done much the same way except that generally only leather and bone are used as the carbon source. You have to watch the temperature more closely with color case hardening or the colors wont come out well.

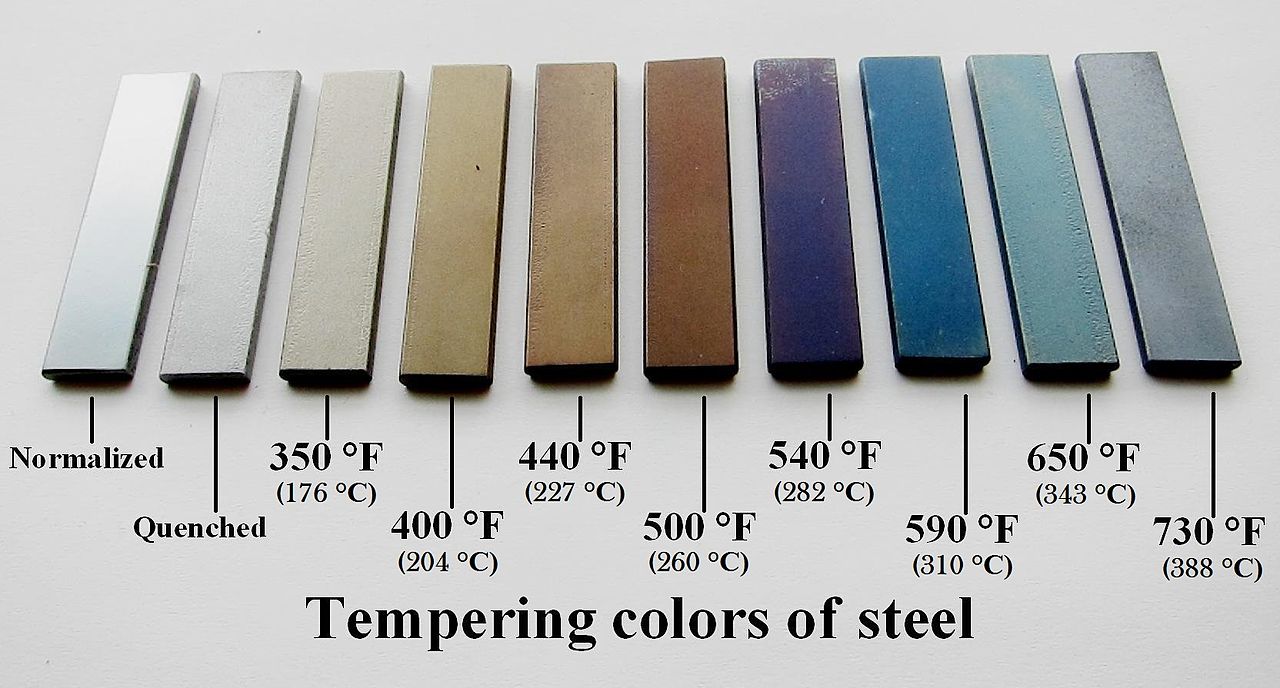

Hardening quenching tempering In case hardening a low-carbon steel case hardening steel with a maximum of 02 carbon is first exposed to a carbon-containing.

Color Case Hardening Turnbull Restoration

Color Case Hardening A Parker Shotgun Midwayusa Gunsmithing Youtube

Induction Heating For Hardening Applications Induction Hardening Solutions

Color Case Hardening Shooting Sportsman Magazine

Basic Color Case Hardening Set Up For Beginers Show And Tell Tngunowners Com

Gun Review Henry Color Case Hardened Edition Rifle In 45 70 Goverment The Truth About Guns

Comparing Induction Hardening Case Hardening 2015 08 10 Industrial Heating

Difference Between Annealing Hardening And Tempering Definition Process Applications Differences

Surface Hardening Processes Bluewater Thermal Solutions

Guns Magazine Case Hardening Redux Guns Magazine

Color Case Hardening Turnbull Restoration

Artstation Bluing Steel Material Sbsar Tga Resources

Color Case Hardening Bubbleheadgunnut

Wyoming Armory Precision Firearms Color Case Hardening Specialists Color Case Hardening Services

The Processes Of Color Case Hardening And Heat Treating 022 Of The Gun Room Podcast

Color Case Hardening Turnbull Restoration